How To Fix An Overwound Grandfather Clock

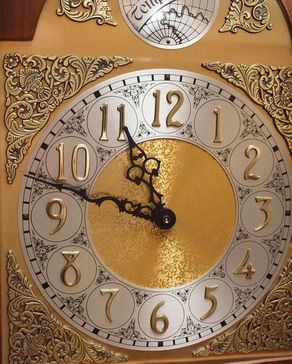

The last thing you wanna do is pour the weights up to high when you re winding the grandfather clock.

How to fix an overwound grandfather clock. Step 2 checking the weight. If they are misaligned set them right by referring to the marks at the bottom. Unwind the carriage clock in half turns and release apply the ratchet between the turns so that the spring pressure is always managed by either your fingers with a firm hold on the key or by the ratchet being allowed to stop the backward movement. We have special tools and equipment here in our repair shop for handling all sizes of mainsprings.

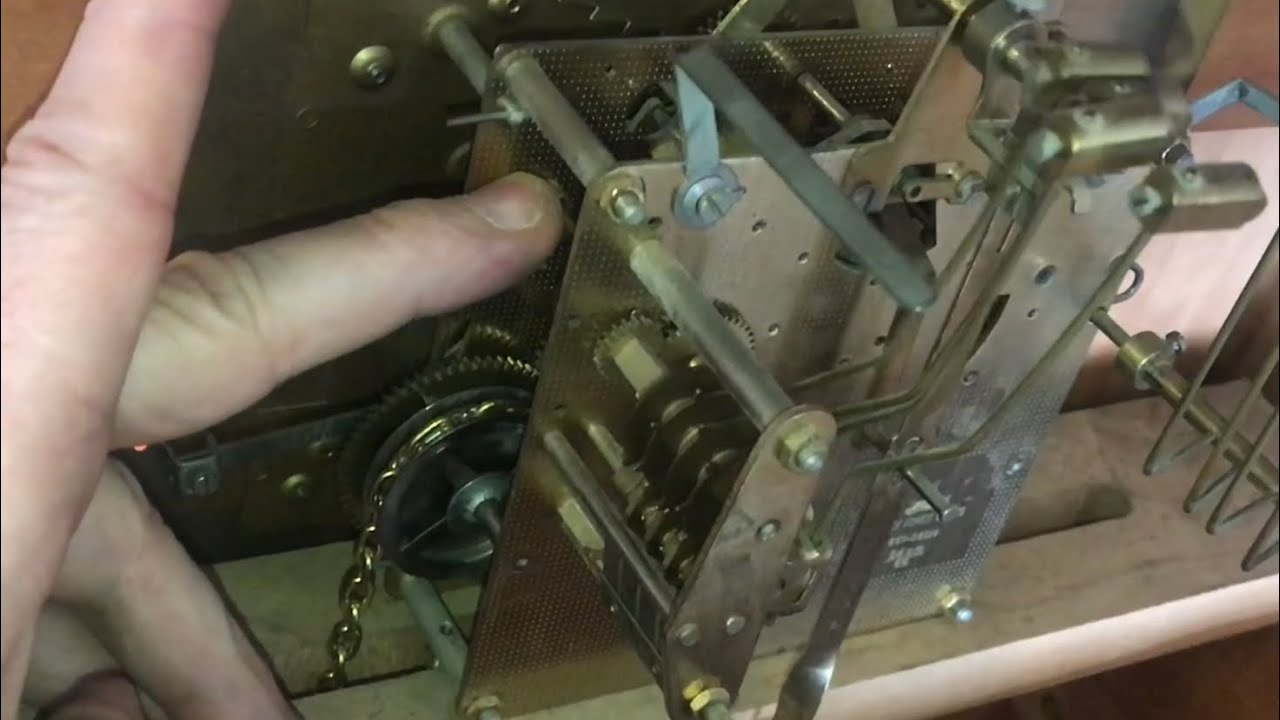

The old urgos spring drive clocks have an arbor that has a small groove cut in it for assembly convenience that will snap if you force it. If this happens you re gonna need to loosen the chains. If we suspect mainspring troubles in your broken clock the first thing we do is remove the mainspring from the clock movement. 2 dip a 12mm paintbrush in rubbing alcohol and slowly brush it over the pinion teeth and pivots.

How to unwind an overwound clock. How do i fix an overwound grandfather clock. I have seen some clocks that have been forced so hard that the arbor actually has snapped. You want to stop just short of the fullest wind possible.

Remove the screws that hold the movement housing in place. A weight provides the power required for the time and chime of the clock to function. The easiest way to release it is to keep swinging the pendulum until the weight drops enough to release the pulley. We then determine if we can clean and lubricate it or if we have to replace it.

If you release the key while the ratchet is off the clock may slip its mainspring. If your timepiece has a tiny pendulum you may need to wind it more often. Weights control the grandfather clock movements. Open the movement case and under a bright lamp light and with the aid of a magnifying glass inspect the gears cogs and.

Overwinding can cause the weight pulley to jam under the clock seat board. How do we fix it. Some clocks will run faster if they are wound too tightly in the first 24 hours after you ve tightened the mainspring. If a clock needs repair and it is wound fully many times the mainspring will stick.

The more you take the time to wind the more wear you are putting your clock through.