Husky Weight Distribution Hitch Setup

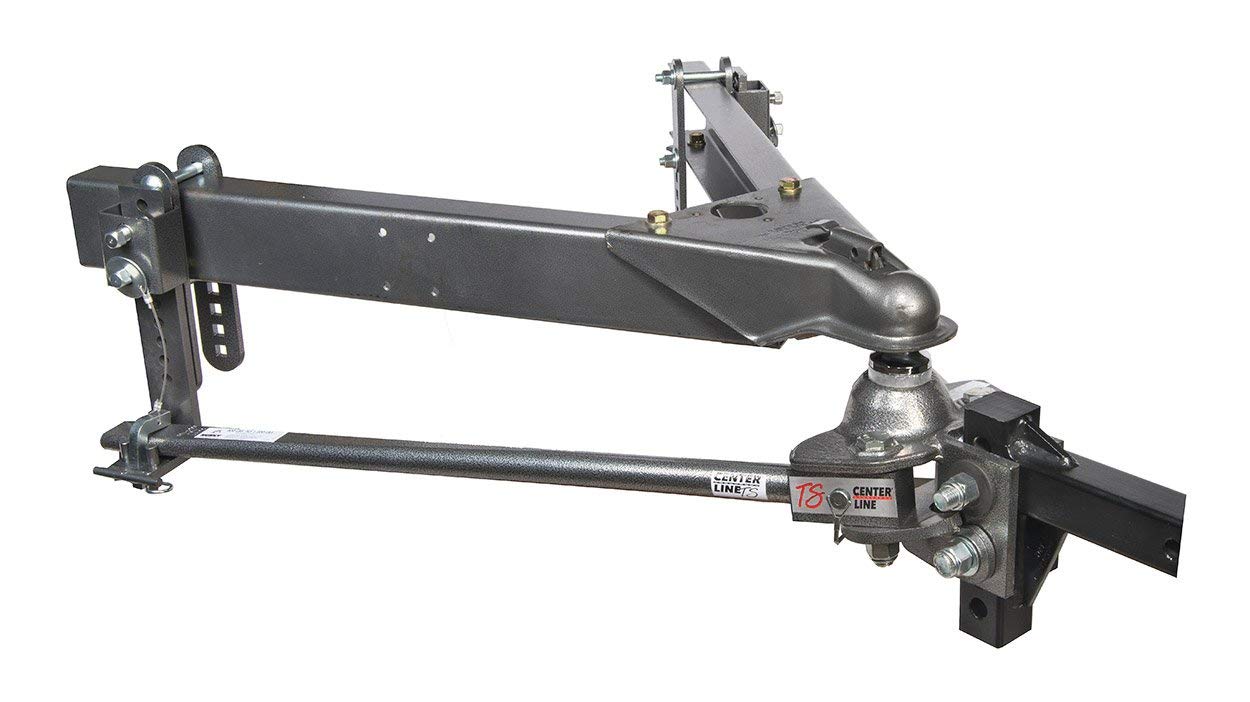

Factory video showing the design capability features and principles behind why the husky centerline hitch is the best on the market.

Husky weight distribution hitch setup. 9 easy steps on setting up weight distribution hitch step 1. This husky towing weight distribution hitch shank rise 7 1 2 inch and drops 9 1 2 inch. If you want to add more tension for the big wind and thus increased sway you can raise those brackets to add more resistance to the trunnion bars. Measure and record the height to pavement here.

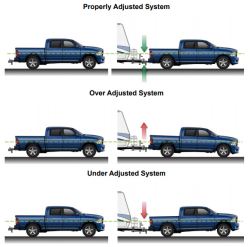

The husky center line weight distribution w sway control trunnion 12 000 lbs gtw 1 200 lbs tw ht32218 may not have the bars level with the frame based on the bracket height needed to optimize the ride of your trailer. Position your trailer and towing vehicle on level ground then take note some of the. Front fender to pavement. This husky towing weight distribution hitch sway control kit includes side bar handle tongue ball plate sway control ball and hardware.

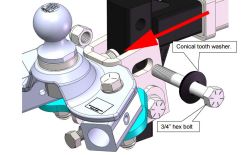

Setting up the hitch ball. To obtain proper ball height on low ground clearance tow vehicles shank may be oriented in the. Add to cart husky towing 34842 weight distribution hitch sway control ball. Husky towing 30858 weight distribution hitch shank.

Husky towing 30857 weight distribution hitch shank. Installation and setup note. This husky towing weight distribution hitch shank rise 4 1 4 inch and drops 6 1 4 inch. Pick reference points at the top center of the front and rear fender well of towing vehicle.

Husky round bar weight distribution hitches husky towing products. In the case of weight distribution hitches this involves a sequence of steps that measure the effect of the load on tow vehicle and trailer.